Ultrasonic Cleaning Technology for Climbing Holds

In the Palamonti Climbing Gym, the multi-purpose hall of the Italian Alpin Club of Bergamo, Chiara Carissoni describes us the cleaning process of the different climbing holds.

Climbing gym, handholds and ultrasounds

Some people will ask themselves what might be the connection among these 3 elements: an indoor climbing gym, climbing holds and ultrasounds. Well, lately the climbing holds of the indoor climbing gym in the city of Bergamo (Italy) have been cleaned using a sophisticated ultrasonic cleaner.

We used to spend our days brushing and descaling several climbing holds with water, soap, vinegar, wire brushes and a lot of elbow grease. We also tried using a water hydro cleaner. The powerful water jet managed to clean all the dirt particles, sweat, grease, and magnesite from the holds, but we still didn’t get perfect results. Most times the dirt was difficult to remove from the cavities so we had to clean the holds again manually. But those days are now over.

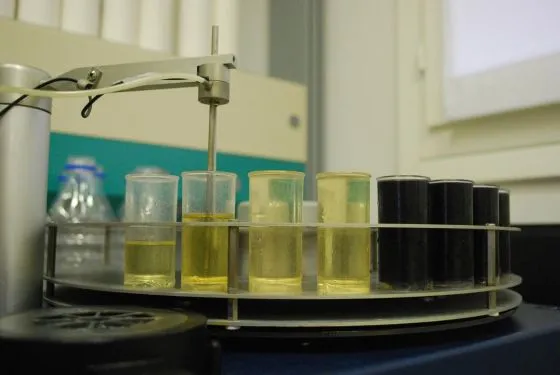

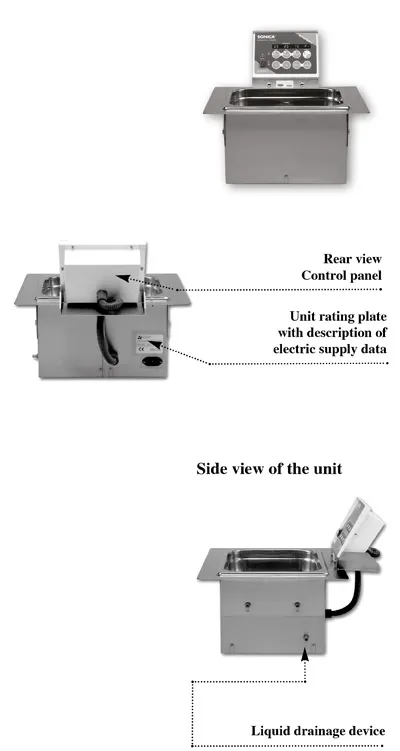

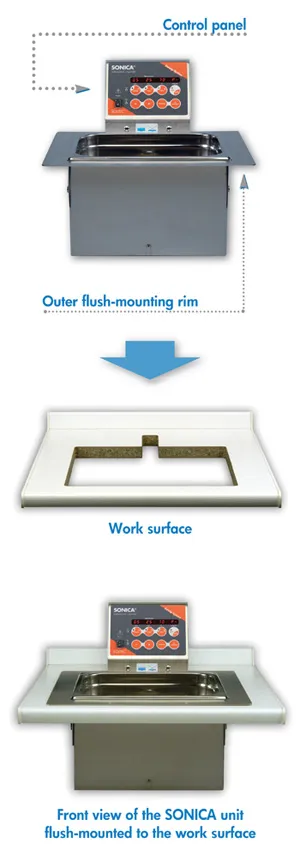

When one of our climber friends showed us SOLTEC’s catalogue, a company specialized in the production of ultrasonic cleaners, SONICA, we decided to take a closer look and that’s how an ultrasonic bath arrived in Bergamo, together with the specific soap for oils and grease.

The instructors and volunteers who regularly help in the maintenance of the gym have been cleaning the climbing holds with the ultrasonic cleaners. Thanks to the ultrasonic technology, the ultrasonic baths clean the magnesite and every other kind of dirt from the climbing holds, making them look brand new.

Our gym is very popular (we have approximately 10 thousands visitors per year) and the climbers use climbing shoes with a special sole and magnesite in order to dry the sweat off their hands and have a more solid foothold.

Moreover, the porous structure of the climbing holds absorb very easily the sweat of the hands together with skins oils and magnesite powder. That’s why the holds become slippery when used very often.

Thanks to SOLTEC and their ultrasonic cleaners we can now wash the climbing holds more often and more easily, making them look brand new.

Other gyms in the Bergamo area have tried this cleaning technology and got excellent results as well.

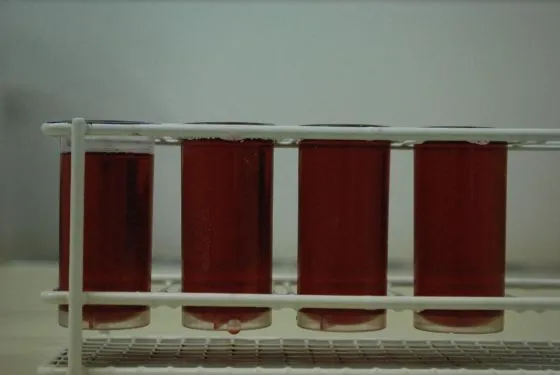

Before the ultrasonic cleaning process.

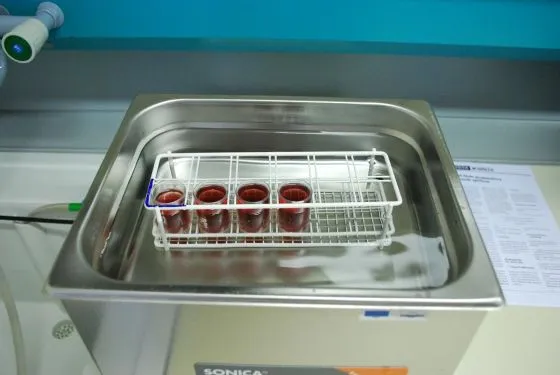

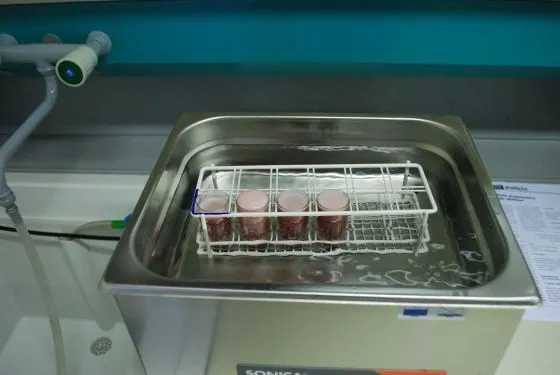

Using the ultrasonic cleaner is very easy: once the tank is filled with water and soap in the quantities needed and already established, you simply put the holds in the tank and that’s it. The timer for the duration of the cleaning cycle needs to be set manually and it depends on the amount of dirt on the holds.

Climbing hold showing residuals of magnesite, rubber and dirt.

Climbing hold after being washed with the ultrasonic cleaner and alkaline degreasing soap.

Once the ultrasonic cleaning process is over, the climbing holds need to be risen to remove any soap residuals and you can start another cleaning cycle. Everything is easier and offers better results.

Thank you, SOLTEC.