Analysis of a new load lifting and handling system manufactured by SOLTEC in Milan

Submitted by soltec-admin on Wed, 09/23/2015 - 20:45

Musculoskeletal diseases and disorders are becoming increasingly important in the fields of occupational medicine and prevention. Over the years, a clear association has been observed between such disorders and working conditions prevailing in various companies mostly related to tasks defined by or connected with certain manual operations, which can be physically very demanding.

For that reason, such disorders are widespread, which has repercussions in terms of economic and social costs.

Moreover, 2012 data from INAIL show that work-related musculoskeletal disorders are on the increase, accounting for about 56% of all occupational diseases recognized in Europe in Italy, in 2012, there were 26,000 reported cases of work-related diseases related to bone and joint problems.

This fact in itself highlights just how much we tend to underestimate the predisposing factors for these diseases when assessing individual work stations and, as a result, during the risk assessment process as a whole.

According to analyses by the European Agency for Safety and Health at Work, these disorders seem to be caused mainly by manual handling of loads, by heavy physical work, by unsuitable working postures, by performing repeated, sometimes strenuous, movements of the upper limbs and, as an aggravating factor, also by the vibrations produced by work equipment or vehicles.

Annex XXXIII to Italian Legislative Decree No 81/2008 identifies the risk factors that the employer has to watch out for and which may be involved in manual handling of loads, during specific work phases.

These tasks definitely need to be assessed so that preventive measures can be taken to mitigate them, or to eliminate them from individual work phases.

Soltec designs and manufactures SONICA ultrasonic cleaners for professional use in the chemical, pharmaceutical, medical, electronics, military and aerospace industries.

Given the wide variety of uses that such cleaners can be put to, there are different sizes and workloads, which means that the size and weight of the article to be cleaned will also change.

Analyzing the work flow associated with the machine it appears evident that, especially when loading and unloading workpieces, where the loads exceed 5-10 kg or more, the operator performs lifting and handling movements that in particular strain the upper limbs and spine, especially when carried out on a regular basis

throughout the working day.

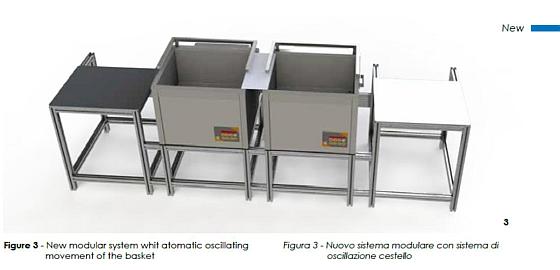

On the basis of these mandatory indications and with a view to making manual labour more efficient and functional , Soltec decided to engineer a lifting mechanism for lifting baskets; this mechanism, with an adjustable counterweight, makes it possible to perform what we might call “assisted” lifting, thus limiting the effort made by the operator or even totally removing it.

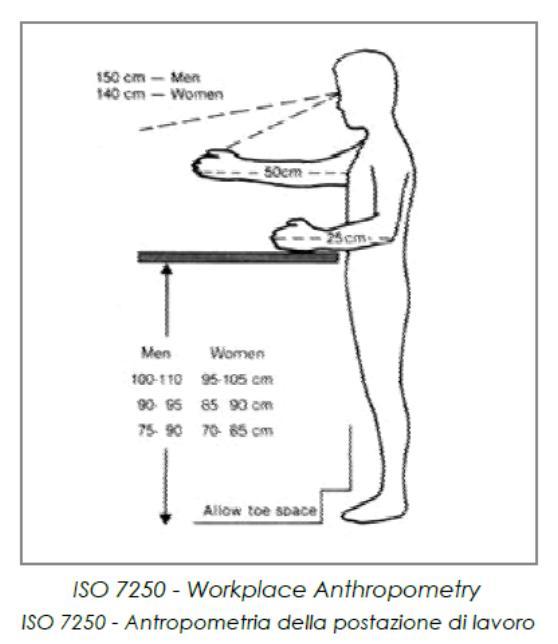

From an ergonomic and research standpoint,we initially analyzed the movements of the user, verifying what the problematic movements and operations were in terms of work and lifting ergonomics.

Thereafter, on the basis of measurements taken at the workstation and from applicable technical standards* data using, amongst other techniques, high-speed cameras and digital crane scales, we were able to analyze the efforts made by the operator for given load ranges and consequently develop a product that was both suitable for making the workstation ergonomically favourable and functional in terms of productivity and load management.

The professional lift designed by SOLTEC, with its modularity and its adjustability to the physique of the operator (height, limb size, weight to be lifted, etc.), enables the operator to lift loads of up to 30 kg keeping the spine in an upright position and the shoulders close to the body, so as not to place any strain on the muscles and thus protect him/her from the effects of muscle tension in the neck and shoulders.

In the case of Soltec’s ultrasonic cleaners, at our assisted workstations the operator will place the object to be cleaned inside the basket, on a shelf at a height that can easily be adjusted at a height that can easily be adjusted in order to minimize strain, and will then raise the loaded basket using the lifting “handlebar” to the right height to place it inside the ultrasonic cleaner. After cleaning, the basket will be lifted out, in assisted mode, and placed back on the work surface, thus making it easy to remove the object.

Franco Beltrame

Industrial Hygienist and Occupational Safety Technician

AL.MA. Consulenza srl

Bibliografy

- D.Lgs 9 Aprile 2008, n°81 – Titolo III , Art. 71/6 – “Uso delle attrezzature di lavoro….” e titolo VI “Movimentazione manuale dei carichi”

- Prof. Enrico Occhipinti – operating and scientific responsible of EPM research center

- UNI ISO 11228 – parte 1 e 3 – “Ergonomics – Manual handling” .

- ISO 11064: 2013 – “Ergonomic design of control center”

- ISO 7250-1:2008 - “Basic Human Body measurements for technological design”

- 3663 reads

- Italiano